UNIPOL™ PE PROCESS

Proven Designs. Limitless Possibilities

THE FLEXIBLE PE MANUFACTURING PLATFORM – FOR TODAY AND TOMORROW

Companies entering or expanding their presence in the polyethylene marketplace share a common goal: proven process technology that maximizes profitability across business cycles and easily adapts to ever-evolving consumer needs. Only UNIPOL™ PE Technology provides a flexible technology platform with full-density product capabilities allowing you to produce a broad range of HDPE and LLDPE applications in a single-reactor platform – including bimodal and unimodal HDPE and metallocene LLDPE and HDPE as well as conventional LLDPE.

The World’s Leading PE Technology

UNIPOL™ PE Technology – centered on the UNIPOL™ PE Process – is the world’s most widely practiced PE technology with more than 165 licensed reactor lines in 28 countries producing more than 48 million tons annually (mTA). That’s approximately one-third of the world’s HDPE/LLDPE output! UNIPOL™ PE Products are recognized and well-received in every corner of the globe offered under the trusted brand names of UNIPOL™ PE Licensees.

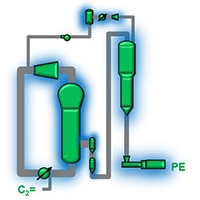

Technically Elegant Design Delivers Mechanical Simplicity

Whereas other PE technologies apply complicated manufacturing systems and more rotating equipment, the UNIPOL™ PE Process keeps it elegantly simple, requiring less equipment and few rotating items, all of which are readily available world-wide. This mechanical simplicity affords multiple benefits for polyethylene producers:

- the industry’s lowest capital investment

- unmatched economies-of-scale

- short project execution schedules

- low operating costs

- robust, reliable operation

With only two primary process areas – Reaction and Purging/ Pelleting – UNIPOL™ PE Plants also fit into a small footprint, providing additional benefits where space is a critical consideration.

Finally, the simplicity of the UNIPOL™ PE Process means fewer operators are required to run and maintain the unit. Additionally, on-stream time, aim-grade production, and lot-to-lot consistency are exemplary, further reducing fixed costs and enhancing return on investment.

Operational Agility

Proprietary technology and know-how contribute to the ability to ramp production rates up and down to meet fluctuating market demand with no impact on product quality. Start-ups and shut-downs are quick and easy, cutting idle times and saving energy and raw materials. Additionally, our UNIPOL™ PE Quick Transition Technology allows a producer to eliminate or minimize transition materials and substantially reduces time and cost associated with significant product transitions.

Unmatched Large Capacity Production Lines

UNIPOL™ PE Technology reactor line throughput is unsurpassed in the PE industry and large reactor line capacity has been proven line after line over the years as we continue to establish new industry records for maximum single-line plant capacities. With current maximum proven design capacity of 650 kTA, UNIPOL™ PE Plants are now operating significantly surpasses the output demonstrated today by any other licensed PE process including other gas-phase, solution, or slurry process technologies.

Unique Integration Savings Through Univation-Linde Alliance

To further enhance the economic advantages of UNIPOL™ PE Technology, Univation Technologies and The Linde Group’s Engineering Division collaborate under a cooperation agreement – referred to as the Univation-Linde Alliance – to deliver unique performance and cost efficiencies for the production of polyethylene resins. Going far beyond simple co-location synergies, the deeply intertwined integration between Linde steam crackers and UNIPOL™ PE Plants allows new-build project owners to realize significantly lower capital costs, operating cost reductions and project execution advantages for projects that include both UNIPOL™ PE Plant(s) and a Linde steam cracker. The Univation-Linde Alliance also provides similar project and operating synergies for UNIPOL™ PE Retrofit Projects. To learn more about how the Univation-Linde Alliance can deliver these measurable benefits for your project, click on the links to the right.

Limitless Possibilities . . .

Univation is committed to keeping UNIPOL™ PE Plants on the cutting edge of technology for decades to come by developing new, advanced product, catalyst and process technologies which can be readily implemented in existing UNIPOL™ PE Plants, regardless of capacity or start-up year.

And when considering future growth potential, UNIPOL™ PE Technology licensees can access a complete range of retrofit technologies for significant plant capacity expansion at lower investment costs and faster project timeline execution versus a new-build construction project. The flexibility of UNIPOL™ PE Technology allows you to forego new construction while achieving significant increases in capacity.

Whether your future objectives are tomorrow’s state-of-the-art products, expanded plant capacity, or further enhancement of your plant’s operating excellence, UNIPOL™ PE Technology offers limitless possibilities…

FIND OUT MORE ABOUT UNIPOL™ PE TECHNOLOGY

Let Univation’s experts assist you in exploring all the opportunities with UNIPOL™ PE Technology for your new PE projects or your existing UNIPOL™ PE Plant.